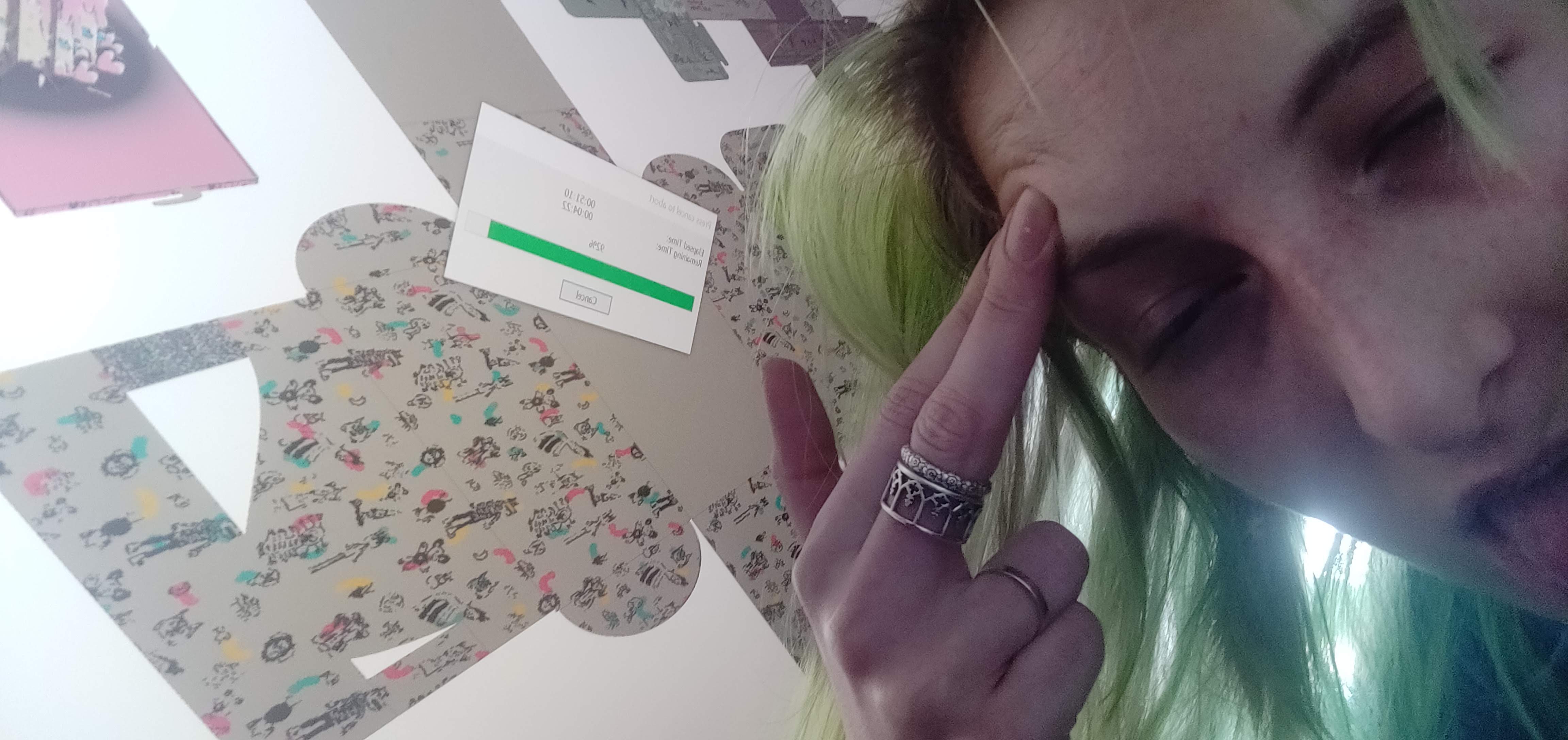

A benefit of the early pandemic days was having the time to focus on my team's entry to the PPA Student Design Challenge in 2020, leading to our first place win, making history as both the first finalist and champions of this competition in both Toronto MetU and Canadian history.

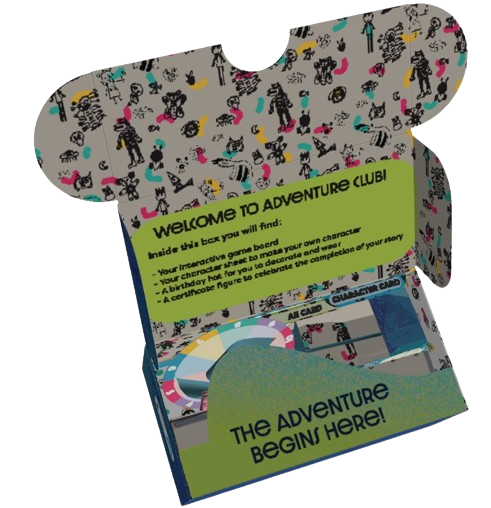

The Paperboard Packaging Alliance (PPA) is a joint initiative of the American Forest & Paper Association and the Paperboard Packaging Council. Their student design challenge for 2020 was to create an educational package for Trees Into Cartons, Cartons Into Trees (TICCIT), an outreach and educational program. The package was aimed at elementary school aged children, with educational content on the sustainability of paper and paperboard packaging, and to distribute the organization's paperboard tree planter.

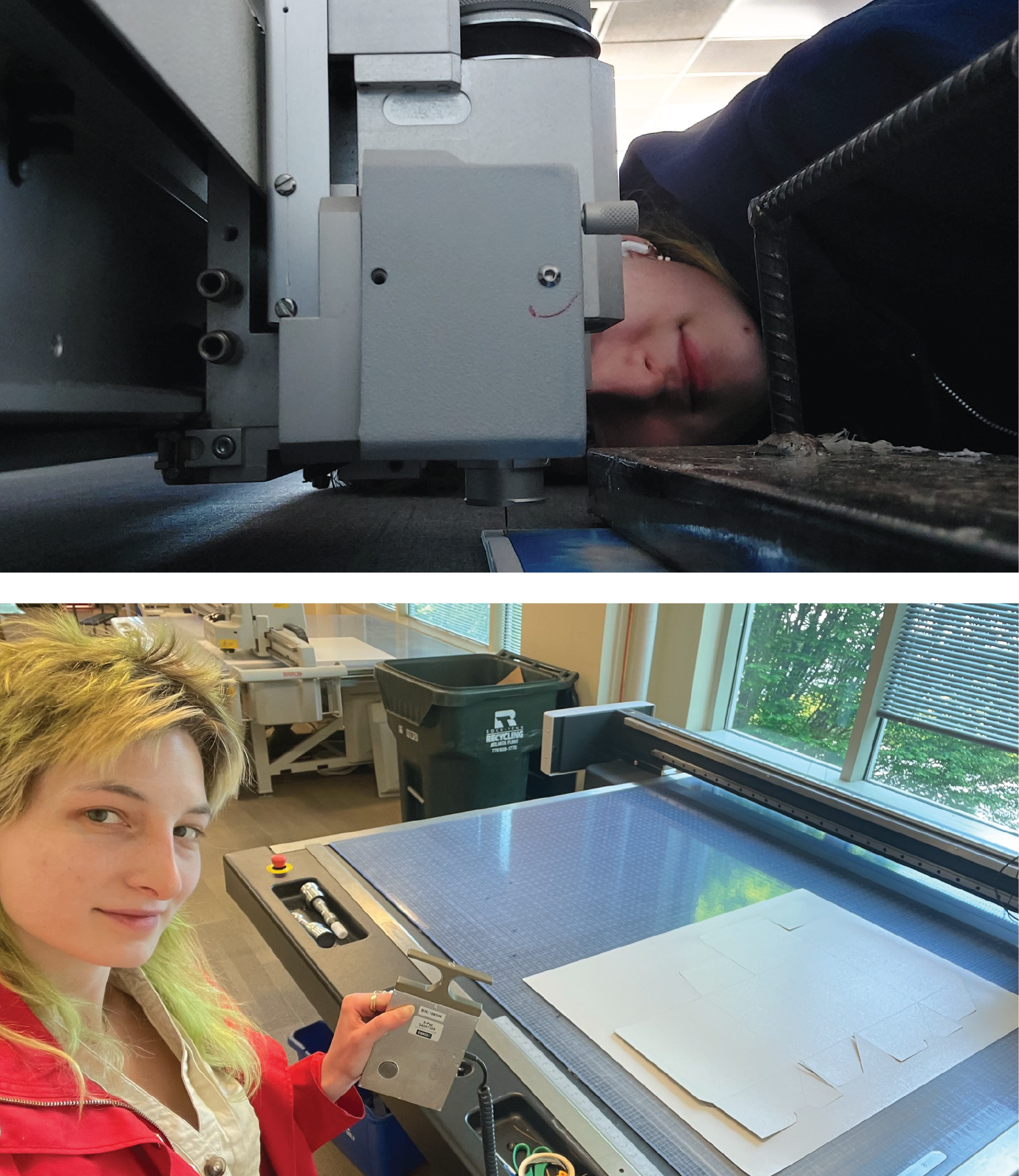

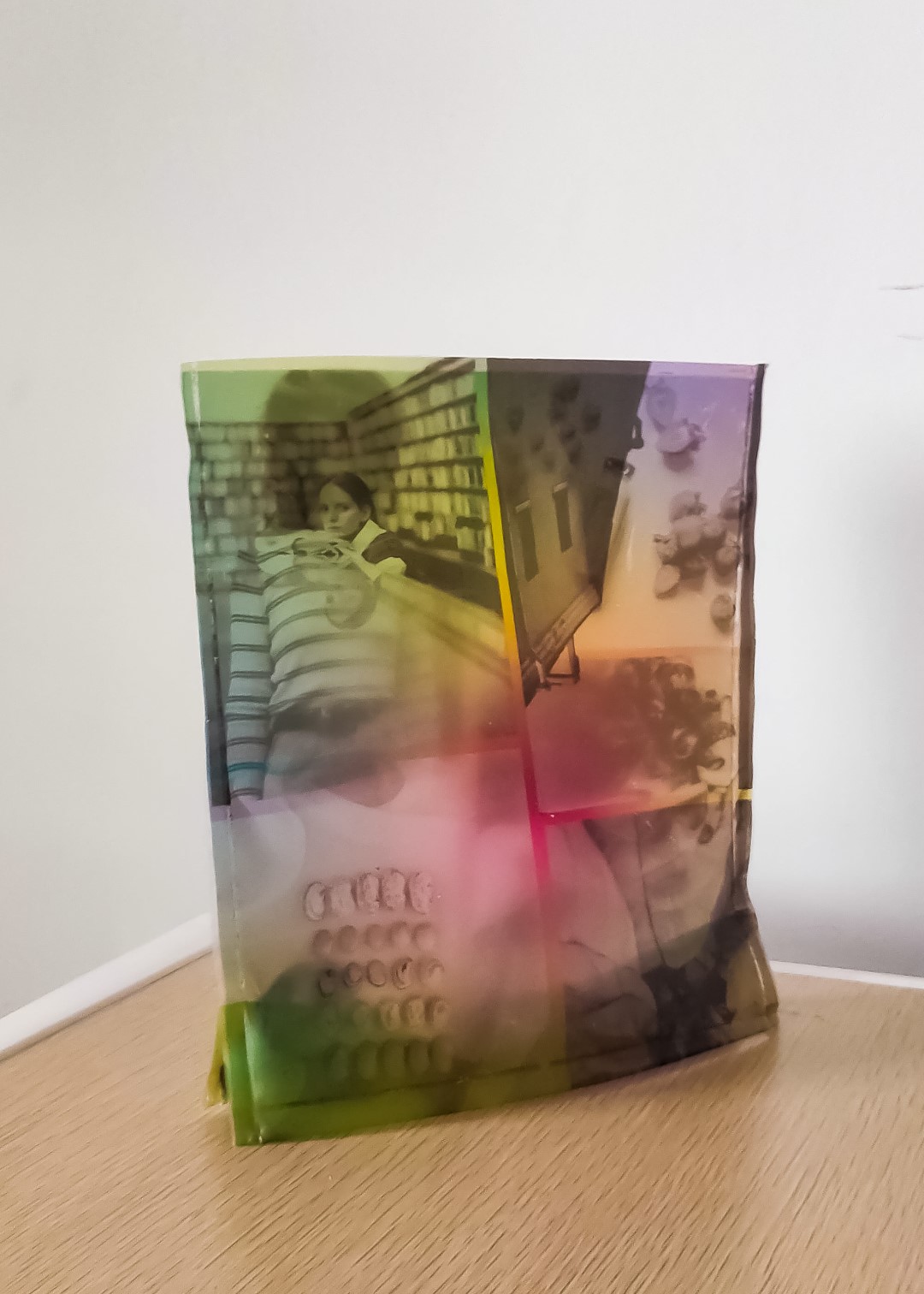

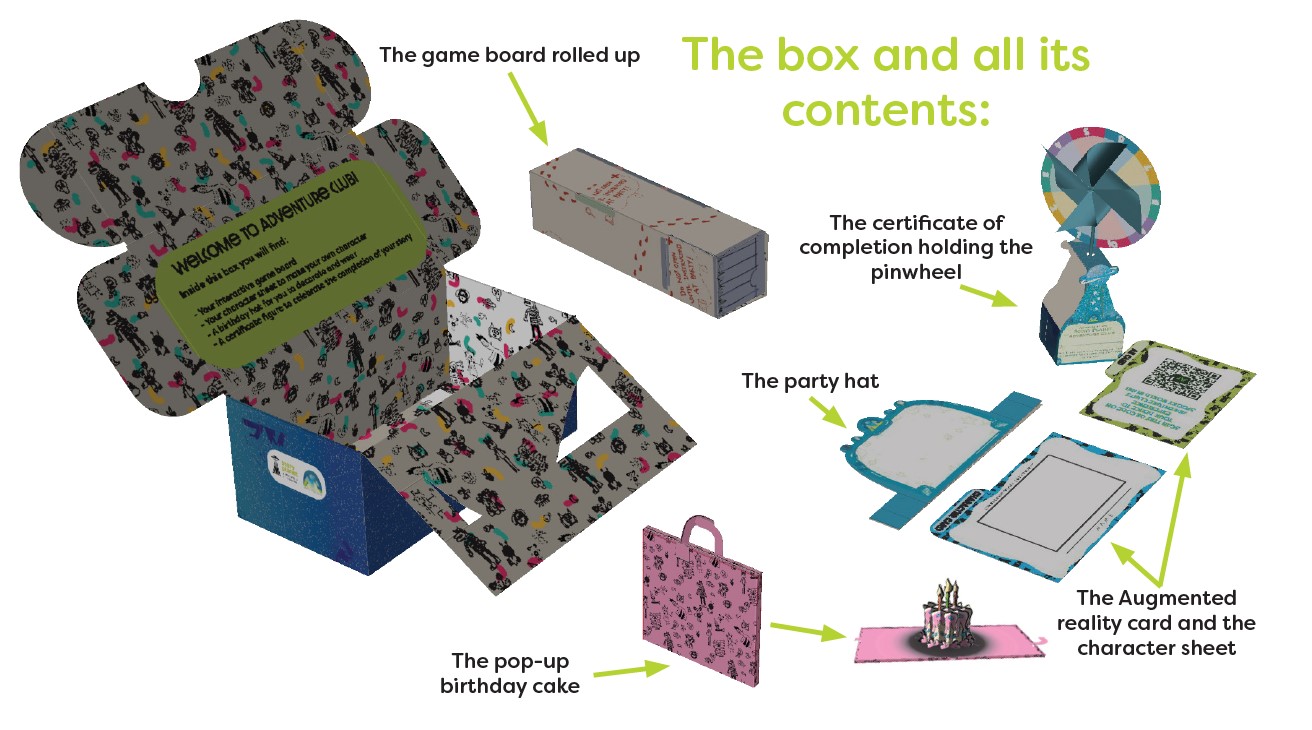

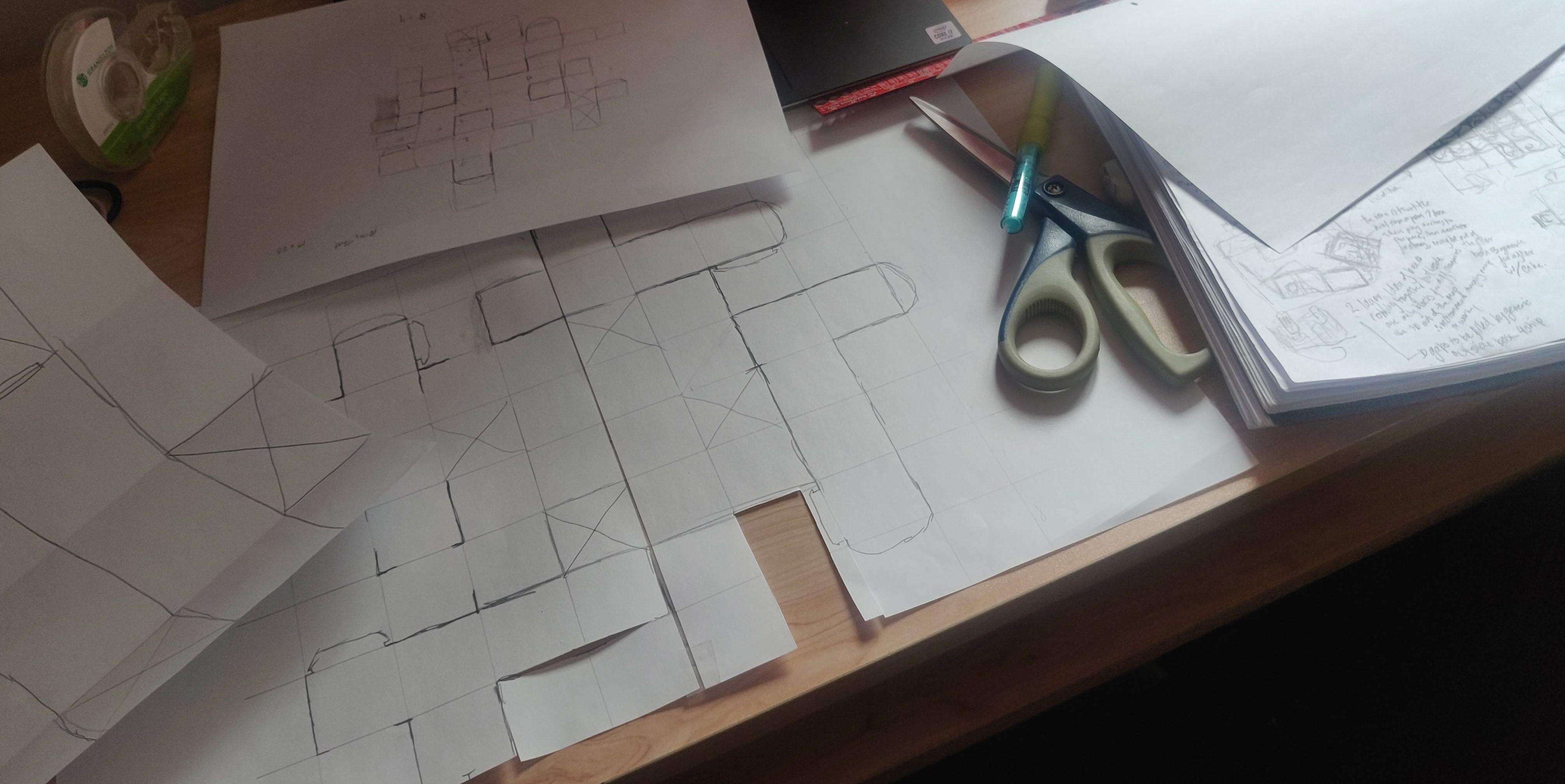

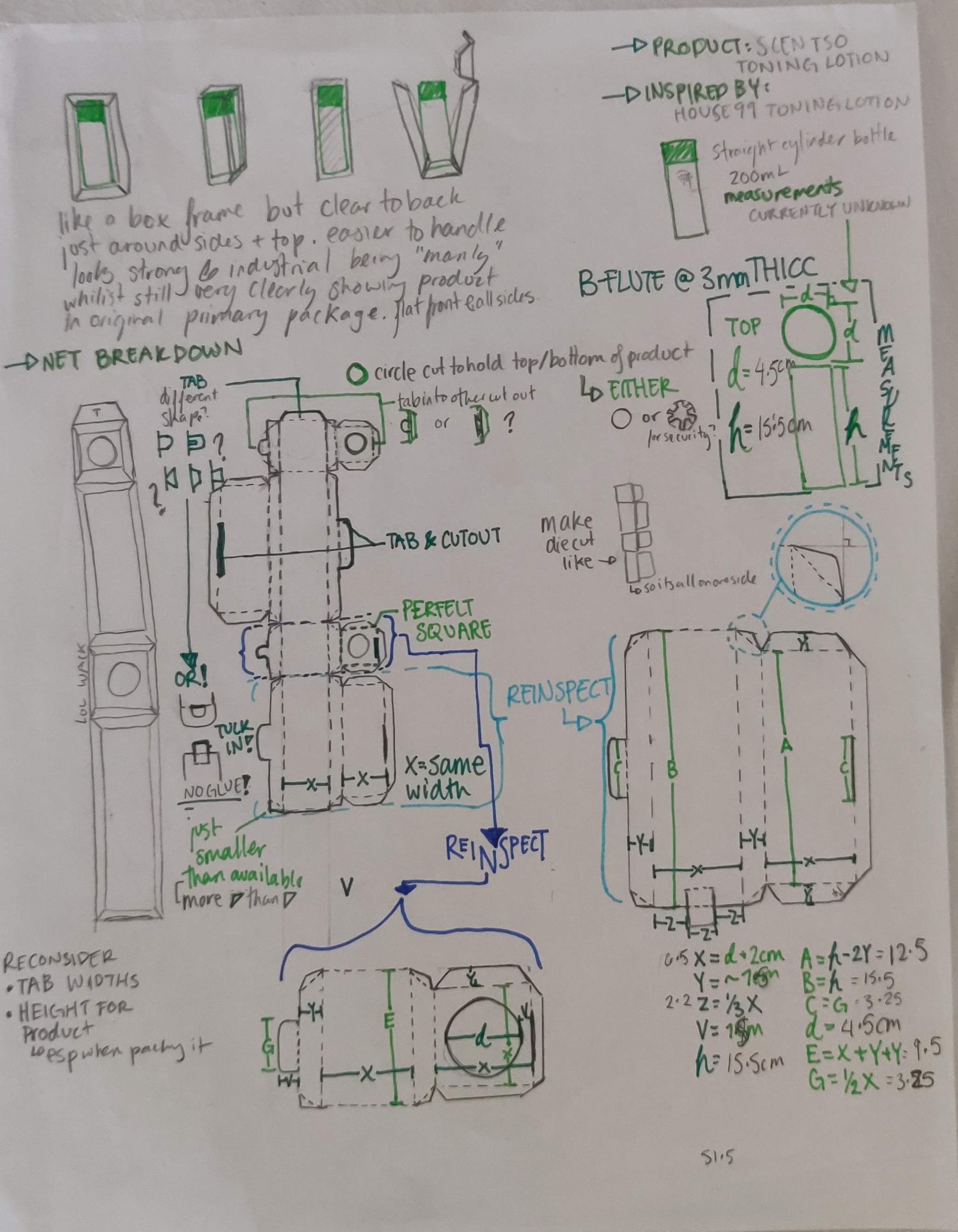

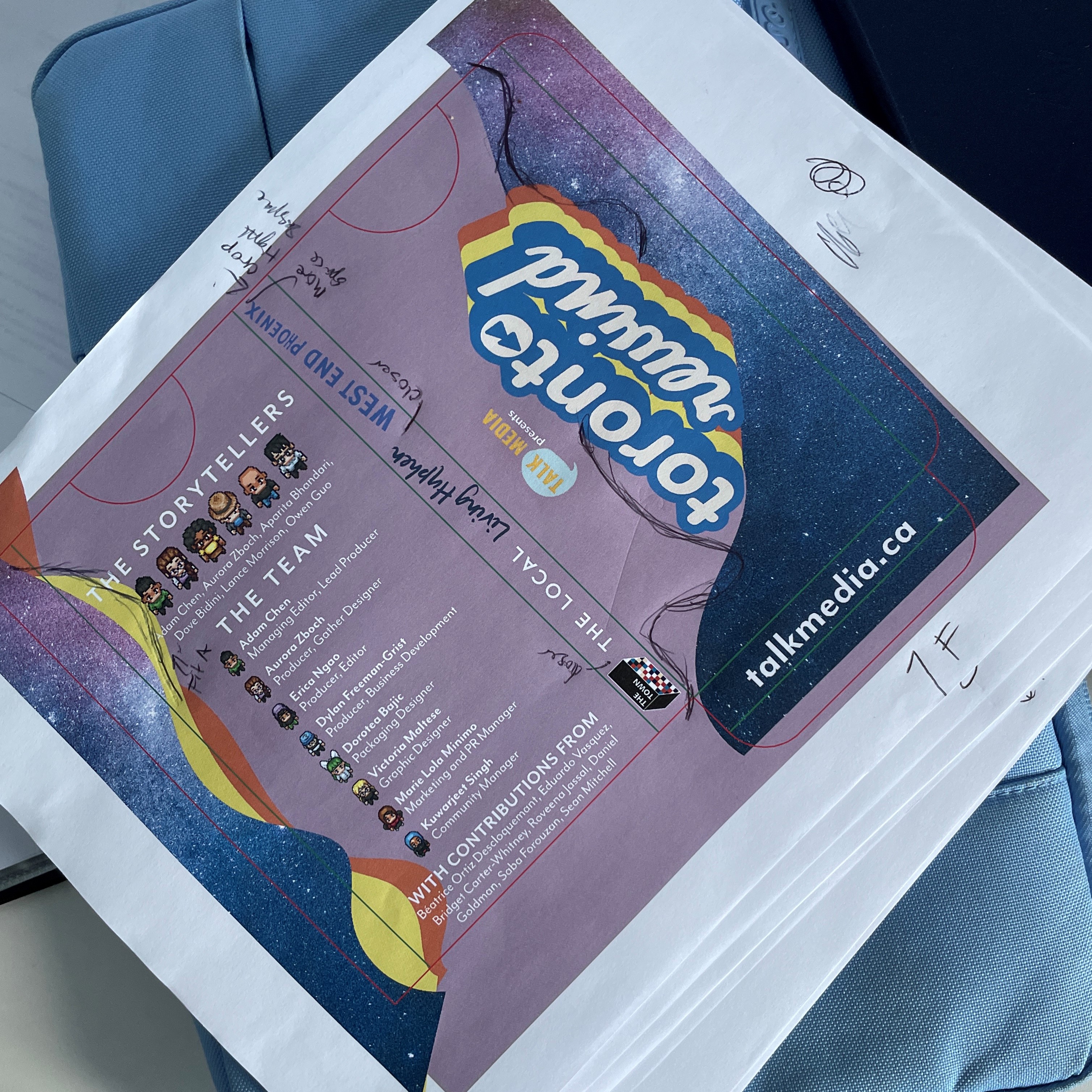

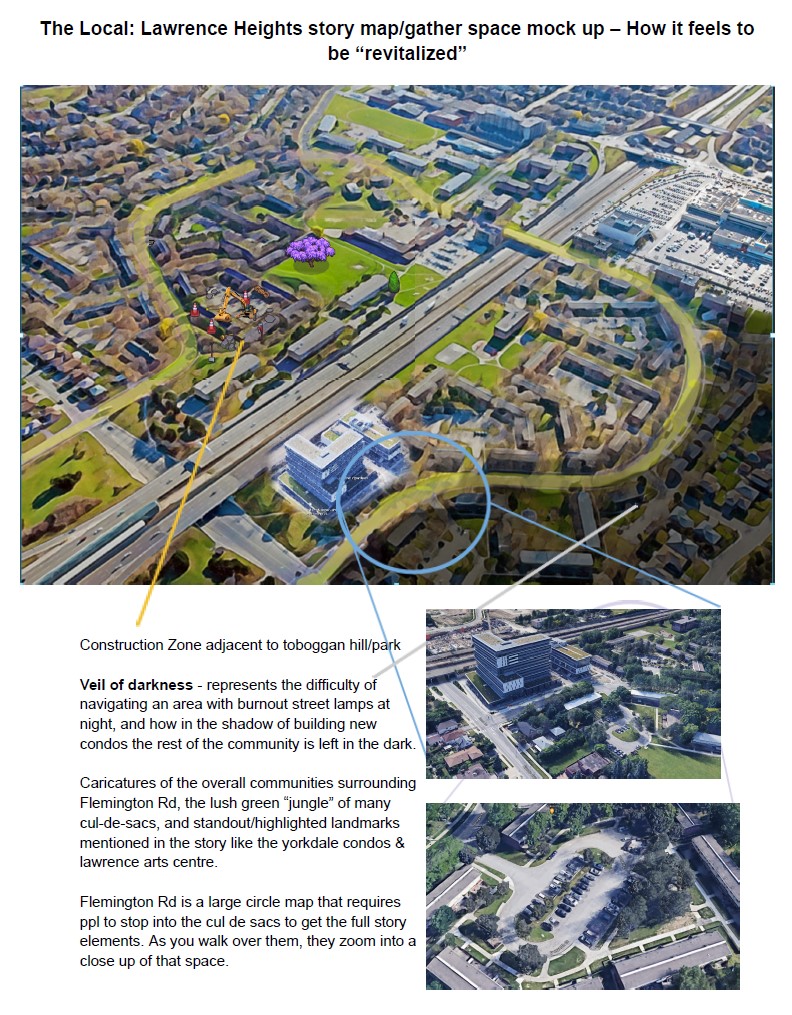

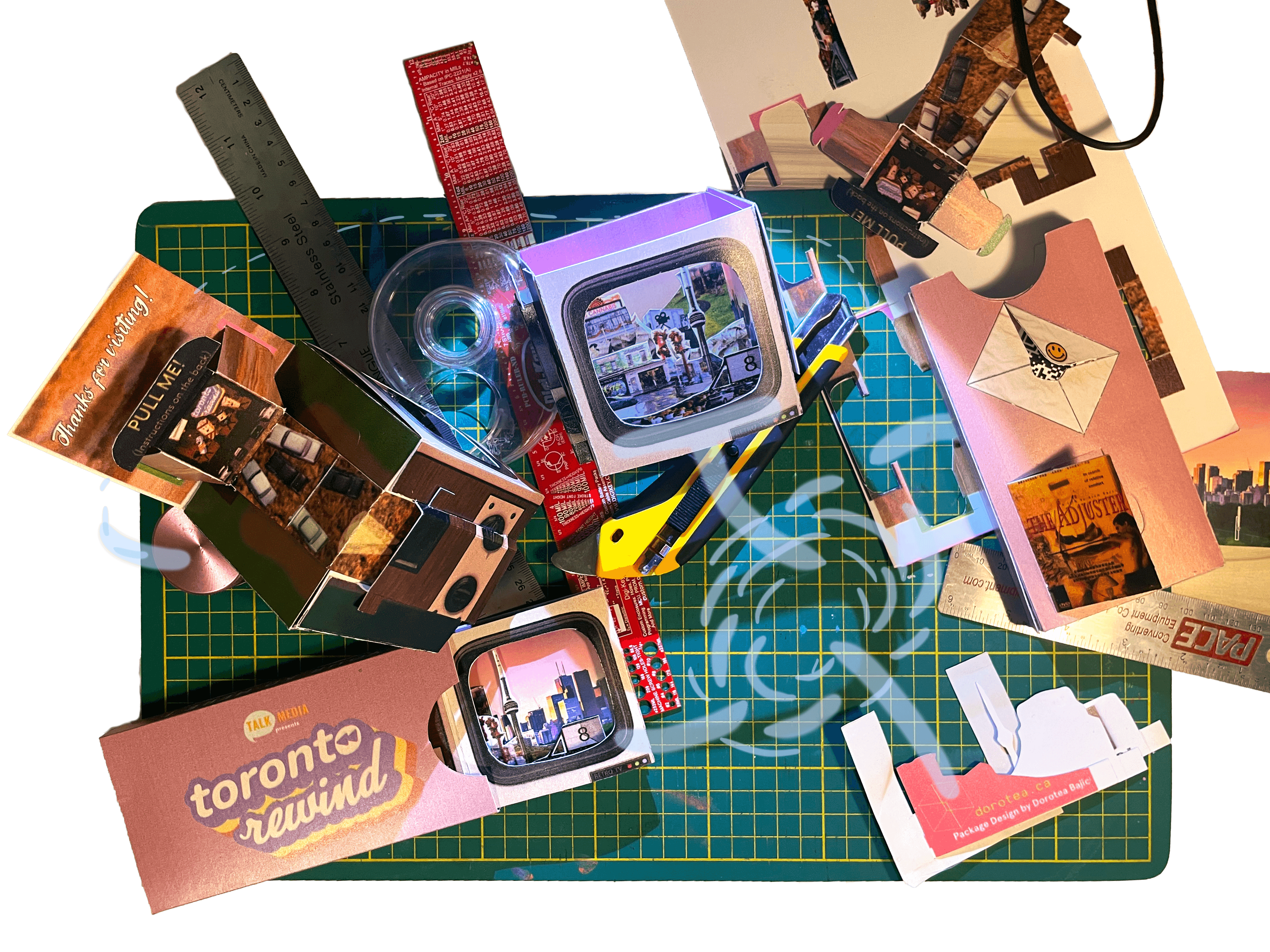

With my focus on concept and structural design and my partner Laura’s strengths in graphic communications and marketing, we created this ready-to-ship toolkit. We approached this challenge with the intention to create something that initiates a positive learning experience for the educators receiving this product. We aimed for an intuitive design which was easy to navigate and exciting to unbox. Rather than focusing only on the visual aspects of the TICCIT packaging, we took a holistic approach and considered structural integrity, graphic manufacturing, user experience, effectiveness of communications, and sustainability using the breadths of technical expertise we learned in our major.

“What impressed me the most as a Packaging Professional was their tenacity and collaborative spirit. Working as a team, in many cases across time zones AND with limited tools, Dorotea and Laura created an impressive hexagonal carton that communicated a sustainability message that was both engaging and fun.”

- Sr. Director of Design, Food and Beverage Americas at WestRock

TICCIT Education Crate - 1st Place PPA SDC

2020

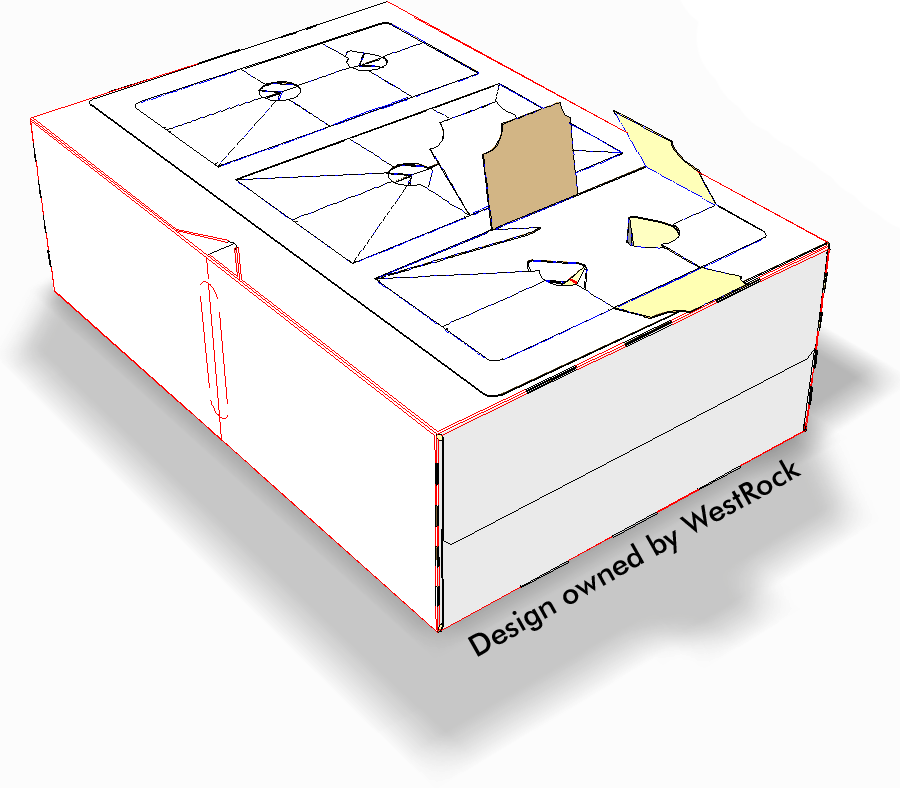

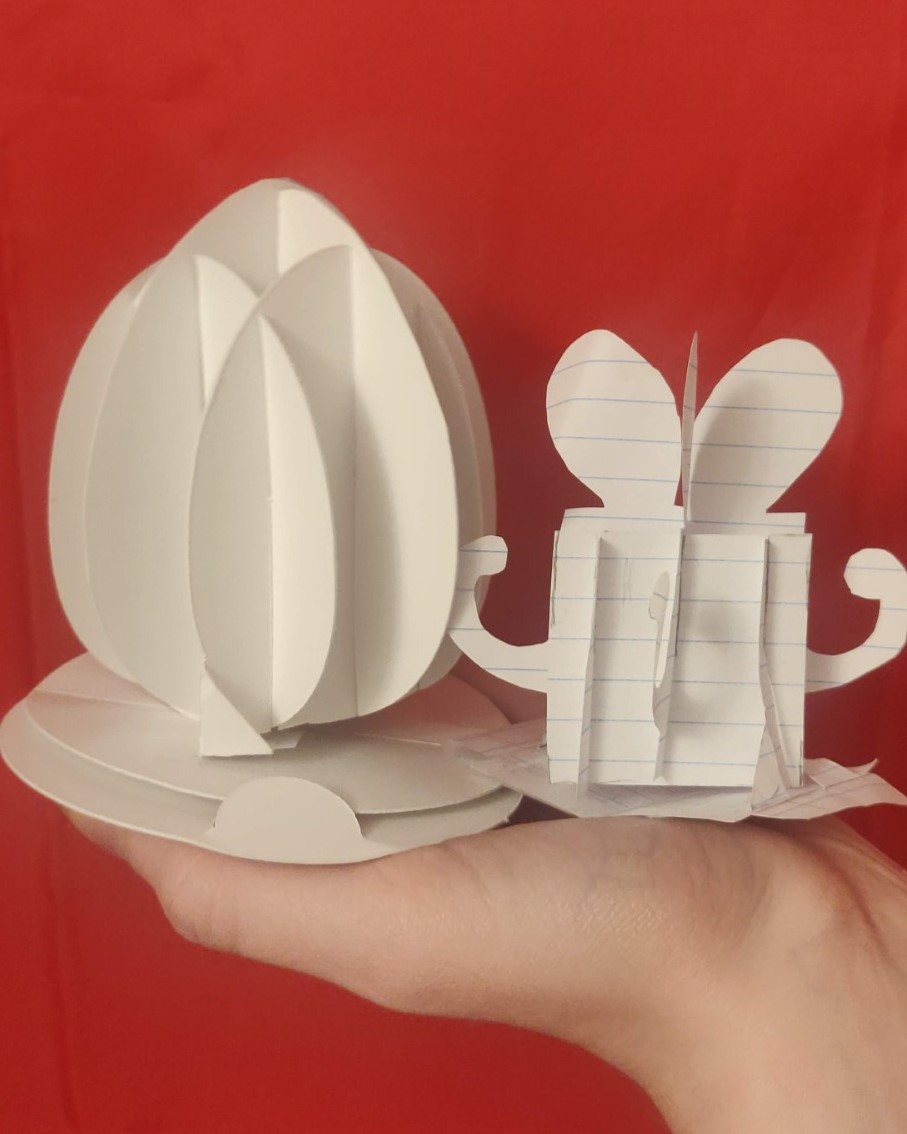

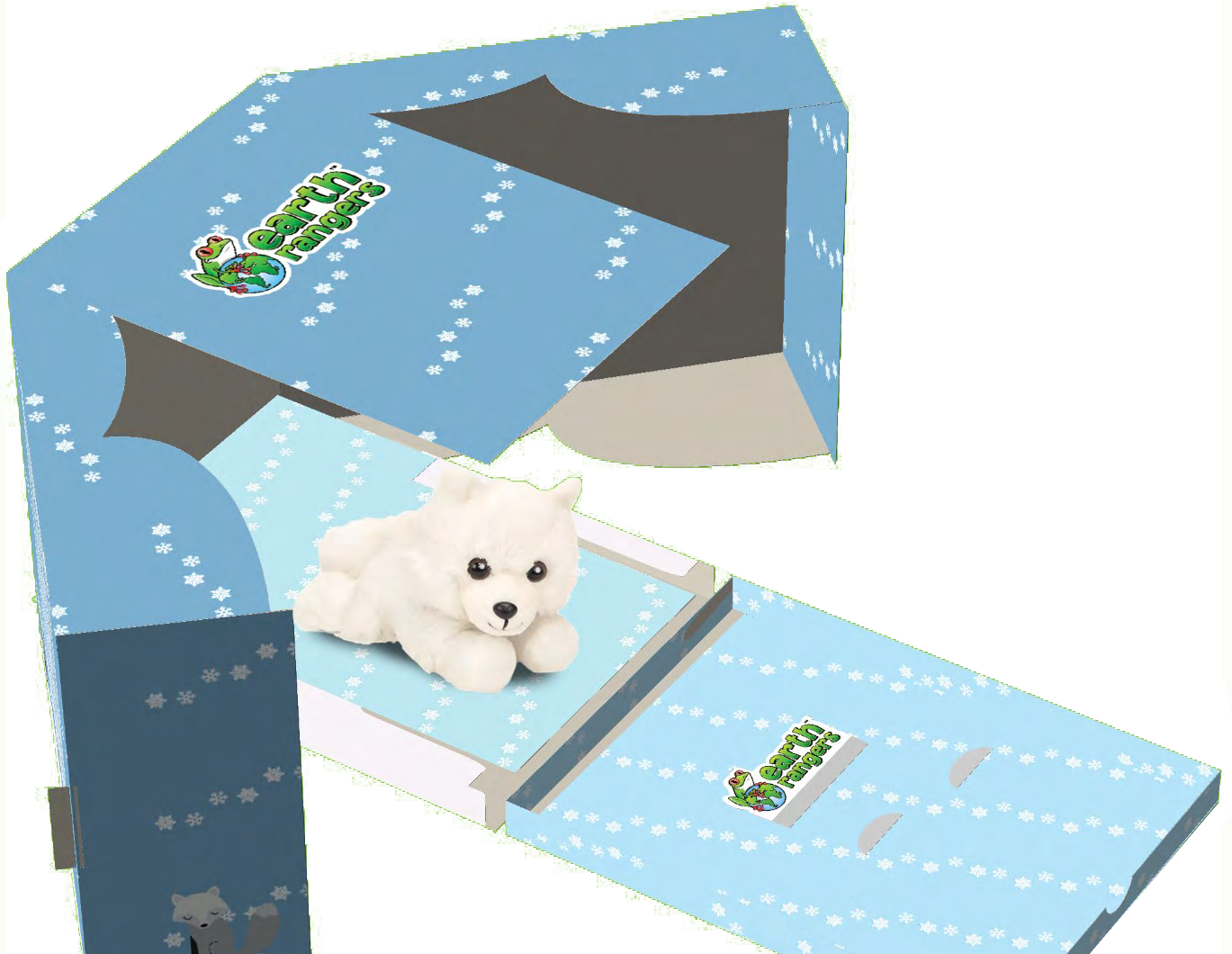

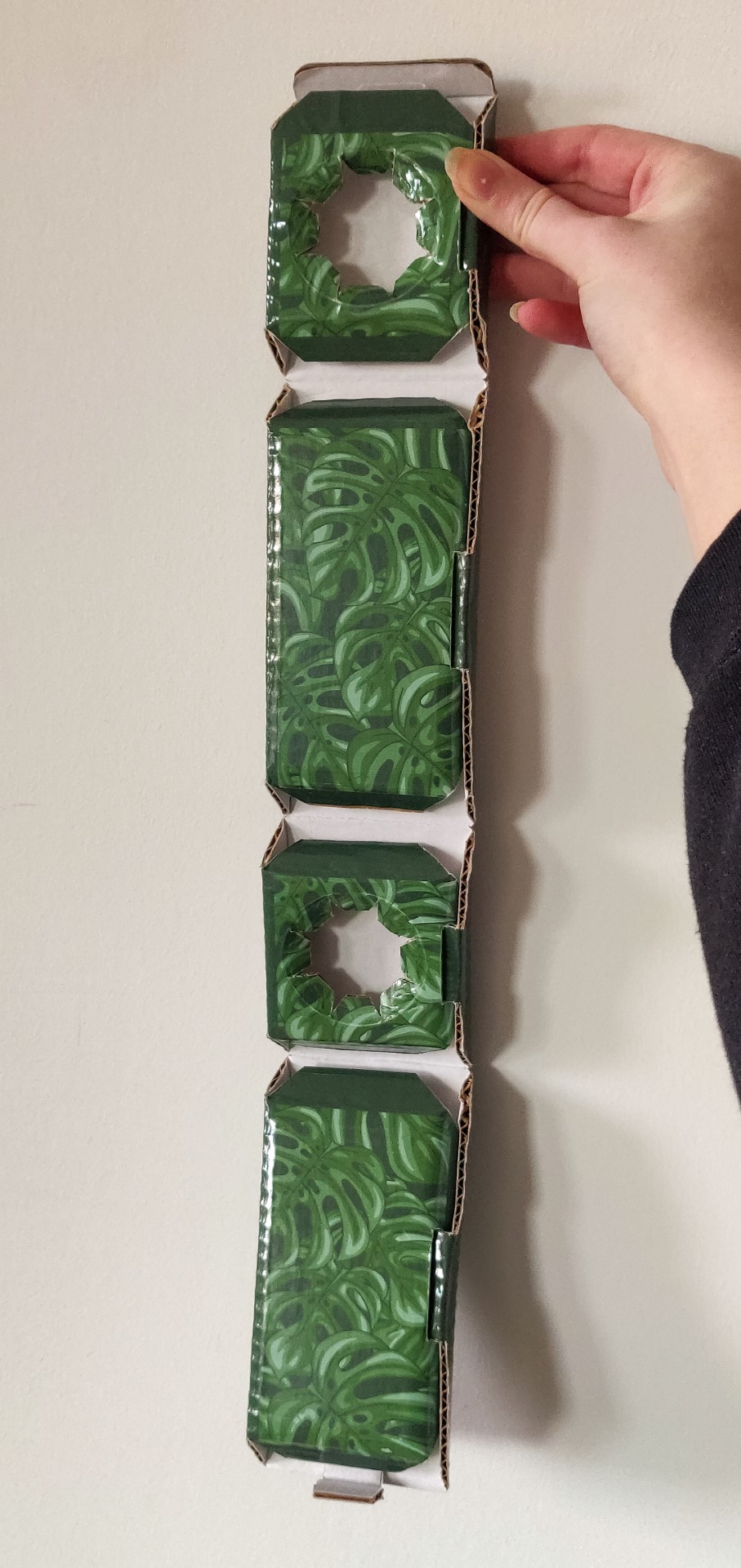

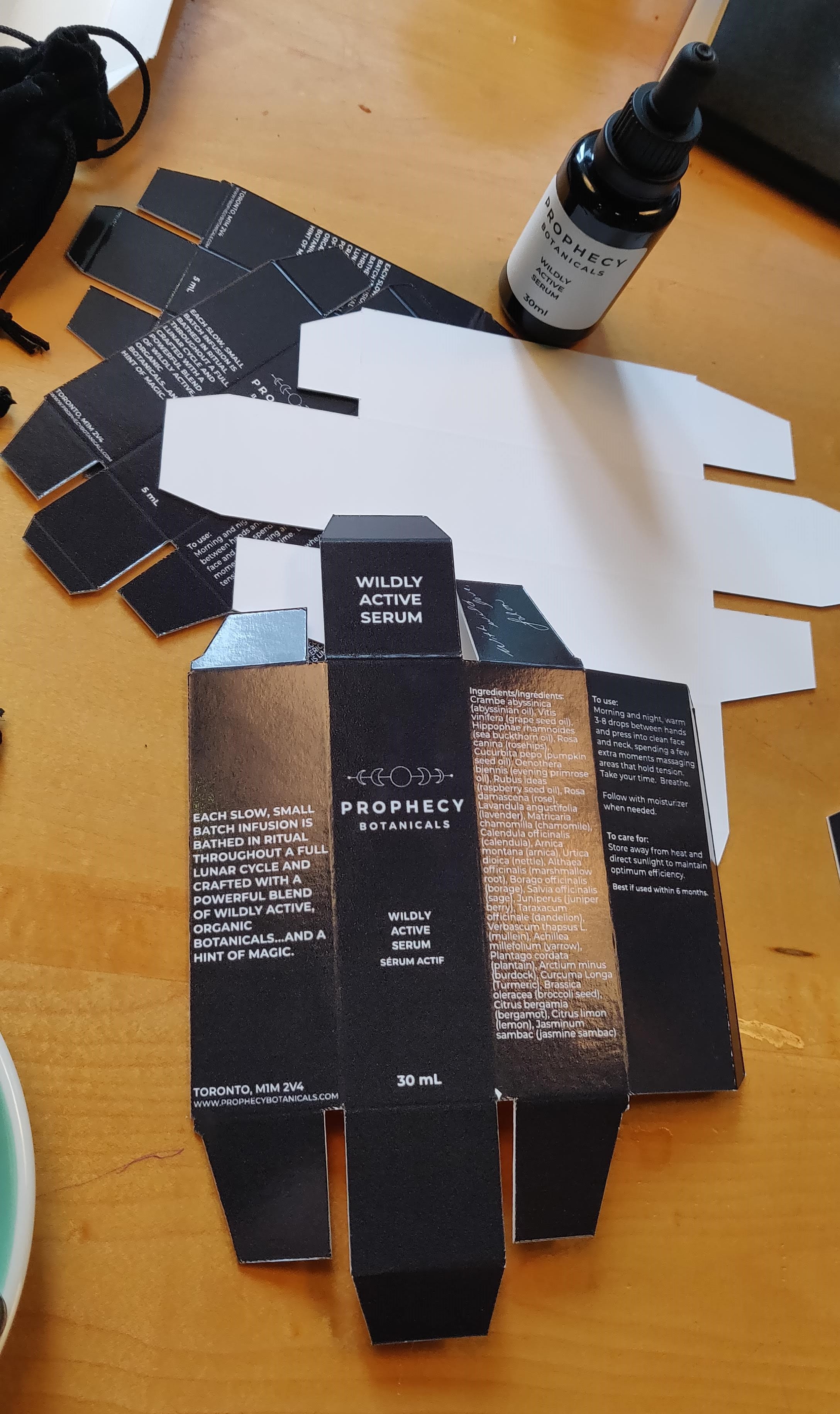

Following the accordion booklet of information, acting as a lid for this pack, is the main compartment. Designed

to feel like a treasure crate shaped in the brand’s logo, containing three smaller glue-less

triangular boxes, an assembled sapling carton, and an additional unassembled

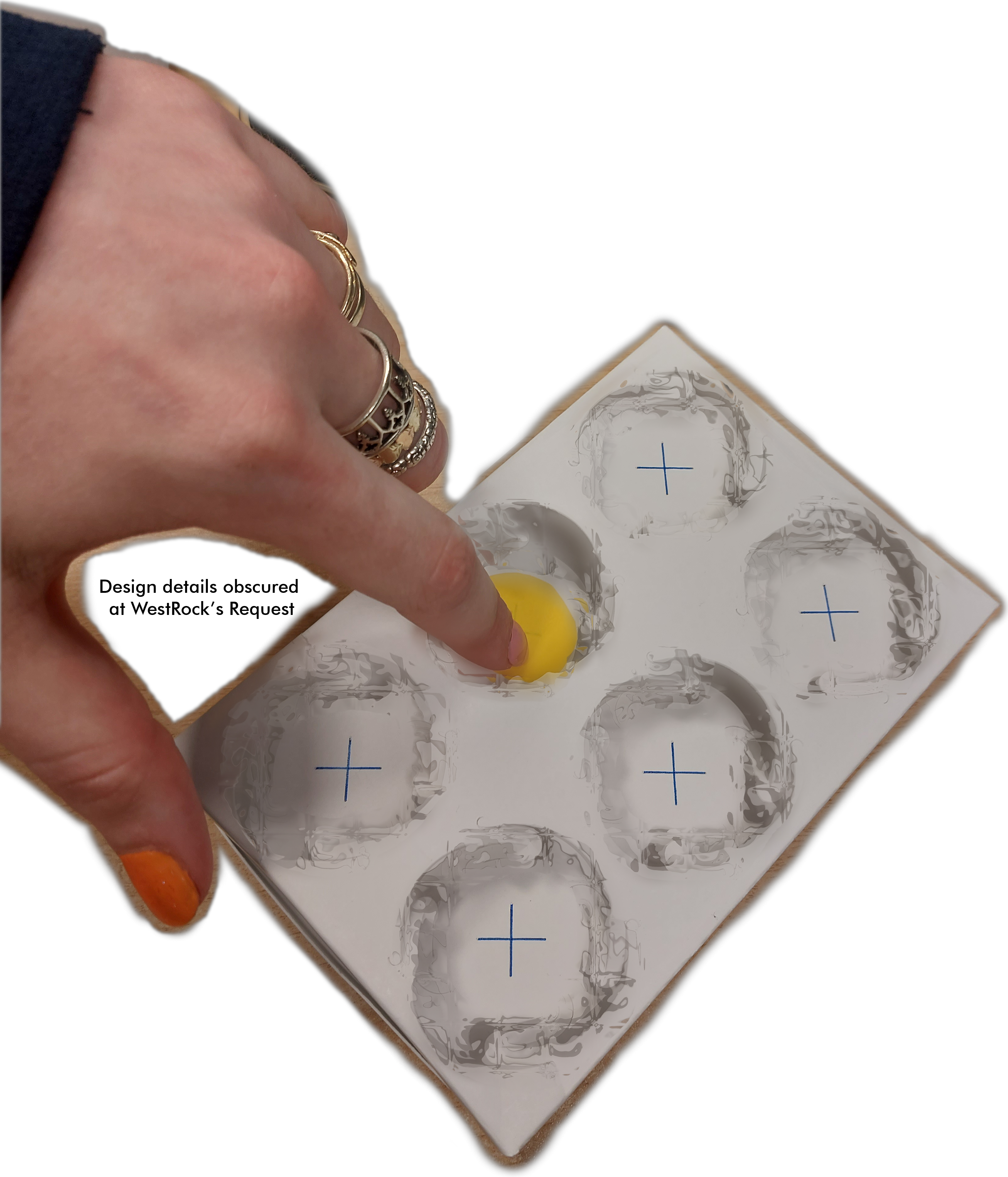

sampling carton. Within the triangular boxes we provided three unique and interactive

activities that keep 8-11 year old students learning and having fun.

Our design included single

sided printing to optimise production time and costs, glue-less structures to enhance

sustainability, entirely paperboard (including the games within which are easy to scan

and duplicate for the classroom) and ready to ship, using shipping labels to bind and

secure.

(1).png)